When using Led Strips in automotive applications there can be concern about over-voltage and sharp voltage spikes.

These are fast, short duration electrical transients in voltage and happen anywhere there is an alternator to charge the battery and other components like fans, solenoids and relays.

In a 12V strip application, over-voltage and spikes can deliver too much power to the LEDs.

This will lower their output faster over-time and in some cases result in thermal runaway,which ends badly.

Eliminate Over-Voltage

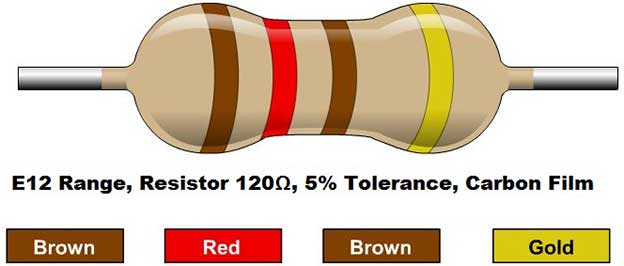

The easiest option is to use a single 120 Ohm resistor (pictured above).

It is the least expensive and time consuming fix and actually takes care of the biggest problem (96% of the issue).

To do it, simply wire in a single 120 Ohm resistor before the LED string.

The 120 Ohm value is only for the type of 12V LED Flexible Strips that we carry and will keep your LEDs running at 100%.

However, this fix doesn’t completely solve the problem, as there is still a chance for short voltage spikes; these spikes can range from 24-50V and result in ruining your LEDs.

Eliminate Short Voltage Spikes

To account for voltage spikes the circuit requires a voltage regulator.

You can use the LM317 designed by Robert C Dobkin in 1976,

which can also solve the problems of voltage and voltage spikes in the car link led strip lights.